To start, you’ll need to familiarize yourself with the necessary materials and basic measurements involved in furniture making. This article will guide you through the process, providing step-by-step instructions and expert tips to help you create a stunning wooden chair.

Key Takeaways

- Understand the importance of precise measurements in wooden chair making.

- Learn about the necessary materials and tools required for the project.

- Discover expert tips and techniques for creating a beautiful wooden chair.

- Follow step-by-step instructions to complete your wooden chair making project.

- Explore common mistakes to avoid in the wooden chair making process.

Understanding the Craft of Wooden Chair Making

To truly appreciate the art of wooden chair making, one must understand its historical context and the benefits of creating something with one’s own hands. The craft of making wooden chairs has a rich history that spans centuries, with designs evolving to reflect the societal, cultural, and functional needs of different eras.

The History and Evolution of Chair Design

The history of chair design is a fascinating journey through time, from ancient civilizations to modern times. Early chairs were reserved for the elite, symbolizing power and status. Over time, chair design evolved, incorporating various styles and materials. The Industrial Revolution brought mass production techniques, making chairs more accessible to the general population.

Why DIY Chair Making is Rewarding

Engaging in DIY chair making offers numerous rewards. It allows individuals to create something unique and functional, tailored to their specific needs and preferences. The process also provides an opportunity to develop woodworking skills and to enjoy the satisfaction of creating something with one’s own hands.

Overview of the Chair-Making Process

The chair-making process involves several key steps, from planning and designing to cutting and assembling the various components. Understanding the chair-making techniques and having the right woodworking tools are crucial for a successful project. The process requires patience, attention to detail, and a willingness to learn and adapt.

By understanding the history, benefits, and process of wooden chair making, individuals can better appreciate the craft and tackle their own projects with confidence.

Essential Materials for Wooden Chair Construction

To create a sturdy and aesthetically pleasing wooden chair, it’s crucial to start with the right materials. The choice of wood, tools, and safety gear plays a significant role in the durability and beauty of the final product.

👉 Click Here to Get Instant Access Now!

Don’t just dream it—build it! Start your next project with confidence today.

Types of Wood Ideal for Chair Making

Selecting the right type of wood is fundamental to crafting a high-quality wooden chair. Teak, cedar, and oak are popular choices due to their durability and aesthetic appeal. Teak is renowned for its resistance to moisture and insects, making it ideal for outdoor furniture. Cedar is another excellent option, offering natural resistance to rot and pests. Oak, with its strength and attractive grain pattern, is a favorite for creating sturdy and beautiful chairs.

Required Tools and Equipment Checklist

Having the right tools and equipment is essential for efficient and safe chair making. The basic toolkit should include a table saw, chisel set, drill press, and sandpaper. Specialized tools like a mortise and tenon joinery kit may be required for specific joinery techniques.

| Tool/Equipment | Purpose |

| Table Saw | Cutting wood to size |

| Chisel Set | Removing small amounts of wood, creating joints |

| Drill Press | Drilling precise holes |

| Sandpaper | Smoothing wood surfaces |

Safety Gear and Workshop Setup Requirements

Safety should always be a top priority in woodworking. Essential safety gear includes safety glasses, hearing protection, and a dust mask. A well-organized workshop with adequate lighting and ventilation is also crucial for safe and efficient work.

By focusing on the quality of materials and safety, you can ensure a successful and enjoyable chair-making experience.

Planning Your Chair Project

A well-planned chair project is the foundation of a beautiful and functional piece of furniture. To achieve this, it’s crucial to understand the various components involved in chair making.

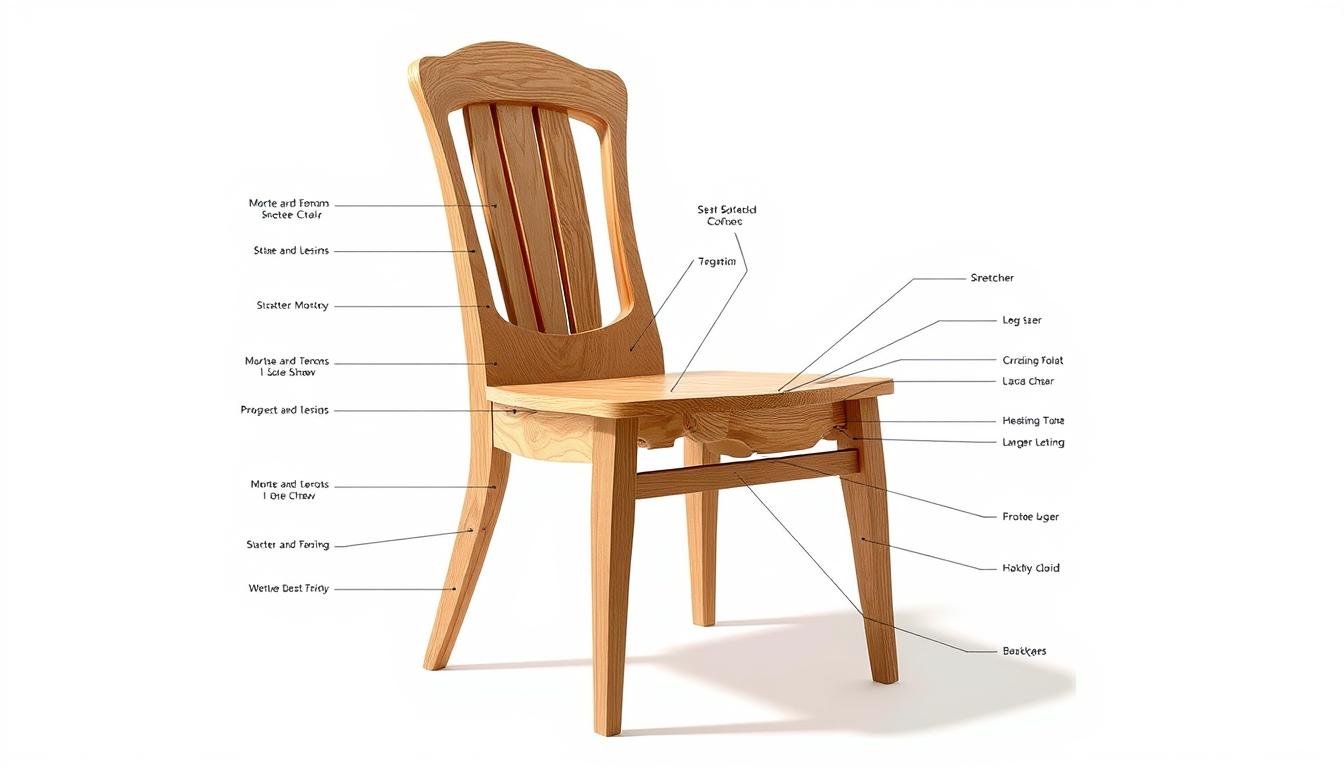

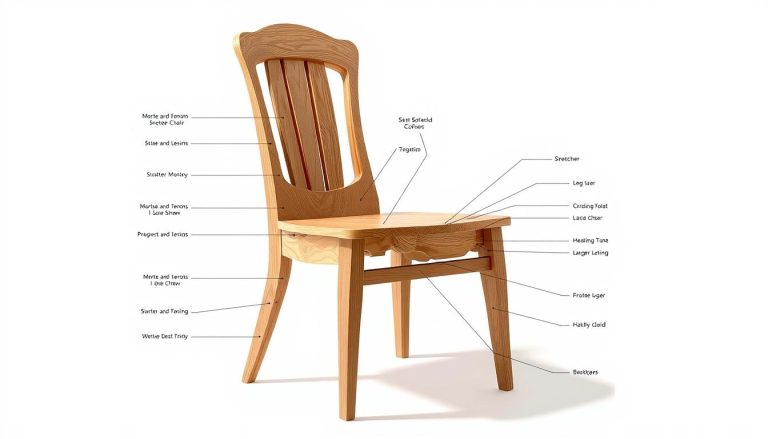

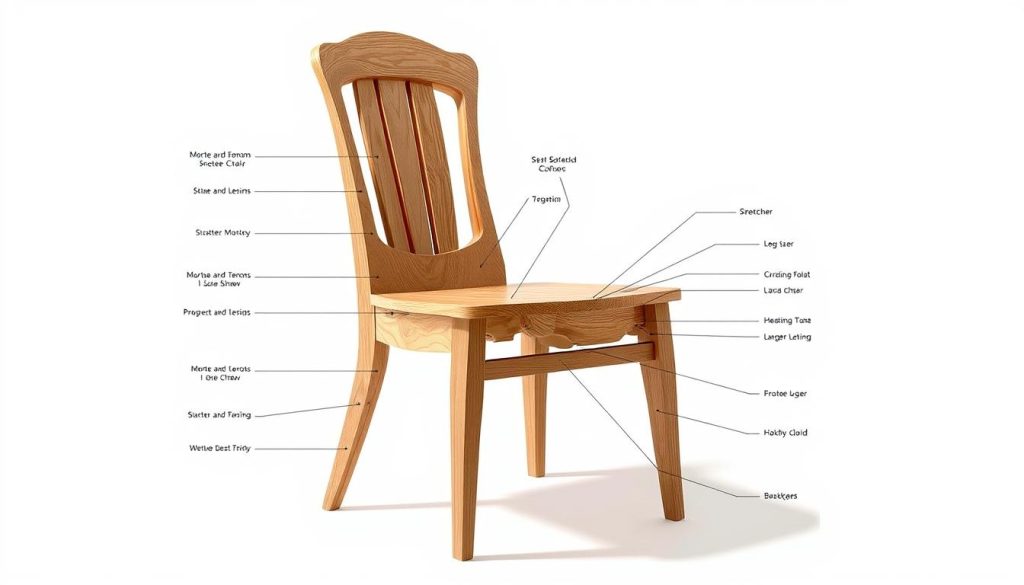

Understanding Chair Anatomy and Components

A chair consists of several key components, including the seat, backrest, legs, and armrests. Each part plays a vital role in the overall structure and comfort of the chair. Understanding these components is essential for creating a well-designed chair.

Selecting the Right Design for Your Skill Level

When selecting a chair design, it’s essential to consider your skill level and experience in woodworking. Beginners should start with simple designs and gradually move to more complex projects as their skills improve. Some popular chair designs for beginners include the Adirondack chair and the simple dining chair.

Creating Accurate Templates and Patterns

Creating accurate templates and patterns is critical for ensuring that your chair components fit together perfectly. You can use various materials, such as cardboard or plywood, to create your templates. It’s also helpful to use software or apps designed for woodworking projects to create digital templates.

By following these steps and considering your design choices, you can create a beautiful and functional chair that meets your needs and enhances your woodworking skills.

👉 Click Here to Get Instant Access Now!

Don’t just dream it—build it! Start your next project with confidence today.

Critical Measurements for Comfortable Chairs

To build a chair that’s not just aesthetically pleasing but also comfortable, one must focus on the key dimensions. The measurements of a chair play a crucial role in determining its comfort and usability. As (furniture making measurements) experts emphasize, precise dimensions are essential for creating a chair that supports the human body correctly.

Standard Seat Dimensions

A comfortable chair starts with the right seat dimensions. Typically, a seat height of 16-18 inches is considered standard, as it allows most adults to sit with their feet flat on the floor or on a footrest, with knees at or below hip level. The seat width should be between 16-20 inches, providing enough space for users to sit comfortably without feeling constrained.

Ergonomic Backrest Angles and Heights

The backrest is another critical component of a comfortable chair. An 人体工程学设计 (ergonomic design) approach suggests that the backrest angle should be between 100-110 degrees, allowing users to maintain a relaxed posture. The height of the backrest should support the natural curve of the spine, typically reaching up to the lower or mid-back area.

Armrest and Leg Proportions for Optimal Comfort

Armrest height and leg proportions also significantly impact the comfort of a chair. Armrests should be adjustable, allowing users to rest their arms at a 90-degree angle, with shoulders relaxed. The legs of the chair should be sturdy and proportionate to the size of the chair, ensuring stability and preventing the chair from tipping over.

As the renowned furniture designer, Sam Maloof, once said,

“The chair is a very difficult piece of furniture to make, because it has to be both beautiful and comfortable.”

By focusing on critical measurements and ergonomic design principles, craftsmen can create chairs that are both functional and aesthetically pleasing.

👉 Click Here to Get Instant Access Now!

Don’t just dream it—build it! Start your next project with confidence today.

The Art of Wooden Chair Making: Measurements, Tips & Pro Techniques

The art of wooden chair making hinges on several key techniques, including precision cutting and effective joinery methods. Mastering these skills is essential for creating a sturdy and beautiful chair.

Precision Cutting Techniques for Accurate Joints

Precision cutting is crucial for accurate joints, which are the backbone of any well-made chair. To achieve precise cuts, it’s essential to use sharp, high-quality tools and to carefully measure and mark the wood. Techniques such as using a table saw or a miter saw can help achieve accurate cuts. Additionally, employing a cutting jig can enhance precision by guiding the wood through the saw blade.

Joinery Methods for Sturdy Chair Construction

The choice of joinery method significantly affects the durability and stability of the chair. Common joinery techniques include mortise and tenon, dovetail, and dowel joints. Each method has its advantages and is suited for different parts of the chair. For instance, mortise and tenon joints are ideal for the legs and frame, providing strong support, while dovetail joints are often used for drawers or other components that require strength and resistance to pull-out forces.

Pro Tips for Perfect Alignment and Assembly

Perfect alignment and assembly are critical for the overall quality of the chair. To achieve this, it’s advisable to create a detailed plan and template before starting the assembly. Using clamps to hold the pieces in place while gluing can prevent misalignment. Additionally, double-checking measurements and ensuring that all joints fit snugly before final assembly can save time and reduce the risk of errors.

By mastering precision cutting, effective joinery methods, and careful assembly techniques, woodworkers can create chairs that are both functional and aesthetically pleasing. Incorporating these woodworking techniques into your projects will enhance your skills and result in high-quality furniture pieces.

Step-by-Step Chair Construction Process

To create a sturdy and comfortable wooden chair, one must follow a detailed construction process. This involves several critical steps, from preparing the wood to assembling the final product.

Preparing and Cutting the Wood to Specifications

The first step in constructing a wooden chair is preparing and cutting the wood according to the specifications of your design. This involves measuring and marking the wood accurately, followed by precise cutting using appropriate tools such as a table saw or circular saw.

Tips for Accurate Cutting:

- Use a sharp blade to prevent splintering.

- Measure twice, cut once to avoid errors.

- Use a miter saw for precise angled cuts.

Creating Strong Joints for Durability

Strong joints are crucial for the durability and stability of the chair. Techniques such as mortise and tenon, dovetail, or dowel joints can be used depending on the design and skill level.

Choosing the Right Joint:

| Joint Type | Skill Level | Strength |

| Mortise and Tenon | Advanced | High |

| Dovetail | Advanced | High |

| Dowel | Beginner | Medium |

Assembling the Chair Frame

Assembling the chair frame involves several sub-steps, including attaching the legs, securing the seat, and installing the backrest.

Attaching the Legs at Proper Angles

The legs should be attached at angles that ensure the chair’s stability. Typically, a slight splay outward is recommended for better balance.

Securing the Seat with Correct Measurements

The seat should be securely attached to the frame, ensuring it is level and evenly spaced. Measurements should be double-checked to avoid any discrepancies.

Installing the Backrest at Ergonomic Angles

The backrest should be installed at an angle that provides optimal comfort and support. An angle between 100 to 110 degrees is generally considered ergonomic.

By following these steps and paying attention to detail, you can create a beautiful and sturdy wooden chair that will last for years to come.

Design Tips for Beautiful and Functional Chairs

Creating a wooden chair that is both aesthetically pleasing and functional requires a delicate balance between design and ergonomics. A well-crafted chair not only provides comfort but also enhances the beauty of a room or outdoor space.

Balancing Aesthetics and Ergonomics

To achieve a balance between aesthetics and ergonomics, consider the chair’s purpose and the user’s needs. For instance, an ergonomic chair for a home office should have a backrest that supports the natural curve of the spine, while also being visually appealing.

Ergonomic considerations include:

- Seat height and depth

- Backrest angle and height

- Armrest height and width

By focusing on these elements, you can create a chair that is both comfortable and stylish.

Weather-Resistant Designs for Outdoor Chairs

For outdoor chairs, durability and weather resistance are crucial. Using woods like teak or cedar, which are naturally resistant to rot and insect damage, can enhance the chair’s longevity.

| Wood Type | Weather Resistance | Maintenance Needs |

| Teak | High | Low |

| Cedar | High | Low |

| Oak | Medium | Medium |

As shown in the table, teak and cedar are ideal for outdoor furniture due to their high weather resistance and low maintenance needs.

Decorative Elements and Personal Touches

Adding decorative elements can make a chair truly unique. Consider incorporating carvings, intricate joinery, or unique finishes to give your chair a personal touch.

“The details are not the details. They make the design.” – Charles Eames

By incorporating decorative elements thoughtfully, you can enhance the chair’s aesthetic appeal without compromising its functionality.

👉 Click Here to Get Instant Access Now!

Don’t just dream it—build it! Start your next project with confidence today.

Sanding and Finishing Your Wooden Chair

A well-sanded and finished wooden chair not only looks great but also withstands the test of time. The process of sanding and finishing is crucial in wooden chair making, as it enhances both the appearance and durability of the piece.

Progressive Sanding Techniques for Smooth Surfaces

To achieve a smooth surface, it’s essential to use progressive sanding techniques. Start with coarse-grit sandpaper (about 120-150 grit) to remove any imperfections or wood fibers. Gradually move to finer grits (180-220 grit) for a smoother finish. For an ultra-smooth surface, finish with a high-grit sandpaper (320 grit or higher).

Choosing the Right Finish for Indoor vs. Outdoor Use

The choice of finish depends on whether your wooden chair is for indoor or outdoor use. For indoor chairs, consider using a water-based polyurethane or oil-based varnish. For outdoor chairs, use a finish that is resistant to UV rays and moisture, such as an exterior-grade polyurethane or a penetrating oil finish like teak oil.

| Finish Type | Indoor/Outdoor Use | Characteristics |

| Water-based Polyurethane | Indoor | Easy to apply, dries quickly |

| Exterior-grade Polyurethane | Outdoor | UV-resistant, durable |

| Teak Oil | Outdoor | Penetrates deep, protects against moisture |

Application Methods for Professional Results

To achieve a professional finish, follow the manufacturer’s instructions for application. Typically, apply the finish in thin coats, allowing each coat to dry before applying the next. Use a clean, lint-free cloth or a foam brush to apply the finish, working in the direction of the wood grain.

By following these sanding and finishing techniques, you can create a beautiful and durable wooden chair that will last for years to come.

Troubleshooting Common Chair Making Problems

Common issues in chair making, such as uneven legs or weak joints, can be addressed with the right techniques and knowledge. Whether you’re a seasoned woodworker or a beginner, understanding how to troubleshoot these problems is crucial for creating durable and comfortable chairs.

Fixing Uneven Legs and Wobbling Issues

Uneven legs can cause a chair to wobble, making it uncomfortable and potentially leading to further damage. To fix this, first, identify the uneven leg by placing the chair on a flat surface and checking which leg is not touching the ground.

To correct the issue, you can either shave down the longer leg or add a shim to the shorter leg. It’s essential to ensure the correction doesn’t affect the overall stability of the chair.

Addressing Weak or Failed Joints

Weak or failed joints are a common issue in chair making, often resulting from improper joinery techniques or using the wrong type of glue. To address this, inspect the joint carefully and determine the cause of the weakness.

Rebuilding the joint with proper techniques and materials can strengthen it. Using dovetail or mortise and tenon joints can provide added strength to your chair.

Repairing Wood Defects and Construction Mistakes

Wood defects, such as cracks or knots, can compromise the integrity of your chair. To repair these defects, use a wood filler that matches the color and grain of the surrounding wood.

For construction mistakes, such as misaligned parts, reassemble the affected area with careful attention to detail. Ensuring accurate measurements and cuts is key to preventing such mistakes.

Preventing Common Errors in Future Projects

To prevent common errors, it’s crucial to plan your project meticulously, including creating detailed templates and patterns. Using high-quality materials and following best practices for joinery and assembly can significantly reduce the likelihood of issues arising.

| Common Issue | Solution | Prevention Tip |

| Uneven Legs | Shave down longer leg or add shim to shorter leg | Ensure accurate leg length during construction |

| Weak Joints | Rebuild joint with proper techniques and materials | Use strong joinery methods like dovetail or mortise and tenon |

| Wood Defects | Use matching wood filler for repairs | Inspect wood carefully before construction |

By understanding how to troubleshoot and prevent common chair making problems, you can improve your skills and create more durable, comfortable chairs.

Conclusion: Mastering the Craft of Wooden Chair Making

Creating a wooden chair is a rewarding experience that requires precision, patience, and practice. Throughout this article, we’ve explored the art of wooden chair making, from understanding the craft and essential materials to critical measurements and troubleshooting common problems.

The (art of wooden chair making) involves more than just assembling pieces of wood; it’s about crafting a functional and beautiful piece of furniture that brings comfort and joy to those who use it. By applying the 术 (tips and professional techniques) shared in this article, you’ll be well on your way to creating stunning chairs that showcase your skill.

To truly (master the craft), continue practicing and experimenting with different designs and techniques. With each project, you’ll refine your skills and develop your own unique style. Whether you’re a seasoned woodworker or just starting out, the art of wooden chair making offers a world of creative possibilities waiting to be explored.

FAQ

What type of wood is best for making a wooden chair?

What are the standard measurements for a comfortable chair?

What safety gear is essential for woodworking?

How do I ensure accurate measurements for my chair project?

What joinery methods are best for sturdy chair construction?

How do I prevent common errors in chair making?

What finish is best for outdoor wooden chairs?

How do I fix uneven legs on a wooden chair?

Don’t just dream it—build it! Start your next project with confidence today.